Product Description:

The Bag-In-Box Filling Machine is a state-of-the-art liquid filling machine designed to meet the diverse needs of various industries. Crafted from high-quality Stainless Steel 304/316, this machine offers exceptional durability, corrosion resistance, and hygiene, making it ideal for filling a wide range of liquids including strawberry jam, beer, and juice. Its robust construction ensures long-lasting performance even in demanding production environments, maintaining product integrity and safety throughout the filling process.

One of the standout features of this liquid filling machine is its single filling head, which enables precise and efficient filling operations. The single head design is perfect for businesses that require accuracy and consistency in every fill, minimizing waste and ensuring that each bag-in-box container is filled to the exact specified volume. This is particularly important for products like strawberry jam and beer, where consistency impacts both presentation and customer satisfaction.

The Bag-In-Box Filling Machine operates with an air pressure range of 0.6-0.8MPa, which provides the optimal force needed for smooth and controlled filling. This regulated air pressure ensures that liquids with varying viscosities, from thick jams to lighter beverages like juice and beer, are dispensed cleanly without splashing or foaming. The machine’s pneumatic components are designed for reliability and ease of maintenance, contributing to reduced downtime and higher productivity.

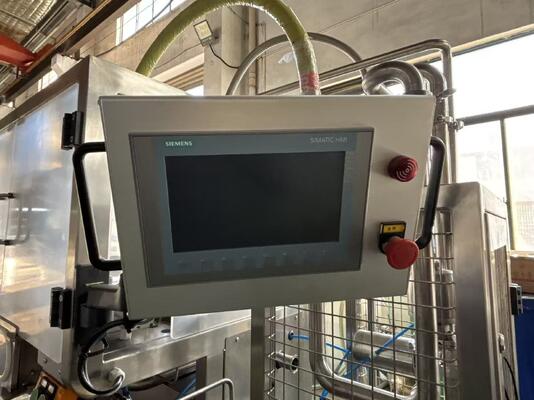

Ease of use is a critical aspect of this liquid filling machine. It features an operating interface entirely in English, making it accessible and user-friendly for operators worldwide. The clear and intuitive control panel allows for quick adjustments and monitoring, reducing the learning curve and enabling efficient operation even by personnel with minimal technical background. This emphasis on user experience helps streamline production workflows and enhances overall operational efficiency.

The versatility of the Bag-In-Box Filling Machine extends beyond just the types of liquids it can handle. Its stainless steel construction complies with strict hygiene standards, ensuring that food and beverage products are filled in a sanitary environment. This makes the machine suitable for use in food processing plants, breweries, and juice manufacturing facilities where cleanliness and contamination prevention are paramount.

In addition to its technical advantages, the Bag-In-Box Filling Machine supports sustainable packaging solutions. By efficiently filling bag-in-box containers, the machine contributes to reducing plastic waste and lowering transportation costs, as bag-in-box packaging is lighter and more compact compared to traditional rigid containers. This aligns with modern environmental goals and consumer preferences for eco-friendly packaging.

Overall, this liquid filling machine is an excellent investment for companies looking to enhance their filling processes with a reliable, precise, and hygienic solution. Whether filling strawberry jam, beer, or juice, the Bag-In-Box Filling Machine delivers consistent performance, ease of operation, and compliance with industry standards. Its stainless steel construction, single filling head, controlled air pressure operation, and English-language interface make it an indispensable tool for modern liquid packaging needs.

Features:

- Product Name: BIB Filling Machine

- High accuracy with ±0.5% filling precision

- Compatible with BIB Bag type for efficient packaging

- Origin: China

- Versatile use for filling Strawberry Jam, Beer, and Juice

- Filling speed ranges from 5 to 20 liters per bag per hour

- Functions as a Bag-In-Box Filler for reliable performance

- Operates as an Automatic Filling Machine to enhance productivity

- Designed as a Bag-In-Box Packaging Machine suitable for various liquids

Technical Parameters:

| Suitable For |

Liquid And Semi-liquid Products |

| Air Pressure |

0.6-0.8MPa |

| Bag Type |

BIB Bag |

| Material |

Stainless Steel 304/316 |

| Use |

Filling Strawberry Jam, Beer, Juice |

| Filling Head |

Single Head |

| Accuracy |

±0.5% |

| Warranty |

1 year |

| Origin |

China |

| Condition |

New |

Applications:

The YGT-BIB-1 Bag-In-Box Filling Machine, proudly manufactured in Shanghai by the trusted YGT brand, is an exceptional solution for various filling needs. Certified with CE and ISO standards, this Bag-In-Box Packaging Machine guarantees high-quality performance and reliability. Designed as an Automatic Filling Machine with a single filling head, it efficiently handles filling speeds ranging from 5 to 20 liters per bag per hour, making it ideal for medium-scale production environments.

This versatile Bag-In-Box Filling Machine is particularly suitable for filling liquid products such as strawberry jam, beer, and juice. Its advanced design ensures precise and hygienic filling, which is crucial for food and beverage industries. Whether you are packaging thick viscous products like strawberry jam or carbonated liquids like beer, the YGT-BIB-1 adapts seamlessly to your production requirements.

Ideal application scenarios for this Bag-In-Box Packaging Machine include beverage manufacturing plants, jam production facilities, breweries, and juice bottling companies. It is especially beneficial for businesses looking to automate their filling process, reduce labor costs, and improve packaging efficiency. The machine operates with an air pressure of 0.6-0.8MPa, ensuring consistent and reliable filling performance.

With a minimum order quantity of just one unit, this Bag-In-Box Filling Machine is accessible for small to large enterprises. Pricing and packaging details are negotiable, providing flexibility to meet diverse business needs. The delivery time is competitively set at 45 working days, and payment terms are via TT, supporting smooth and secure transactions.

Moreover, the YGT-BIB-1 comes with a 1-year warranty, offering peace of mind and dependable after-sales support. Its robust construction and advanced technology make it a valuable investment for businesses aiming to enhance their production line with an efficient, accurate, and user-friendly Automatic Filling Machine.

Customization:

Introducing the YGT-BIB-1, a high-precision Bag-In-Box Packaging Machine designed and manufactured by YGT in ShangHai, China. This Liquid Filling Machine is specially engineered for filling a variety of liquid and semi-liquid products including strawberry jam, beer, and juice, ensuring an accuracy of ±0.5% for consistent and reliable packaging.

Our Bag-In-Box Packaging Machine, model YGT-BIB-1, is CE and ISO certified, guaranteeing compliance with international quality and safety standards. The machine is user-friendly with an operating language in English, making it accessible and easy to operate for global customers.

We offer flexible product customization services tailored to your specific needs. The minimum order quantity is just 1 unit, allowing you to test and evaluate the machine before committing to larger orders. Pricing and packaging details are negotiable to best suit your business requirements.

The delivery time for the YGT-BIB-1 Liquid Filling Machine is approximately 45 working days. Payment terms are convenient and secure, with transactions handled via TT to ensure a smooth purchasing experience.

Choose the YGT Bag-In-Box Packaging Machine for your liquid and semi-liquid filling needs and benefit from advanced technology, precision, and reliable after-sales support. Contact us today to negotiate pricing and customize your liquid filling solution.

Support and Services:

Our BIB Filling Machine is designed to provide efficient and reliable filling solutions for Bag-in-Box packaging. To ensure optimal performance and longevity of your machine, we offer comprehensive technical support and services.

Technical Support:

Our team of experienced technicians is available to assist you with installation, setup, and troubleshooting. We provide detailed operation manuals and training to help your staff operate the machine safely and efficiently. Remote support is also available for quick diagnosis and resolution of any issues.

Maintenance Services:

Regular maintenance is crucial for the smooth functioning of the BIB Filling Machine. We offer scheduled maintenance services, including inspection, cleaning, lubrication, and replacement of worn parts to minimize downtime and extend the machine’s lifespan.

Spare Parts Supply:

We maintain an inventory of genuine spare parts to ensure quick replacement and reduce operational interruptions. Our support team can help identify the correct parts needed for your machine model.

Upgrades and Customization:

To meet evolving production needs, we offer machine upgrades and customization options. Our engineers work closely with customers to implement enhancements that improve efficiency, accuracy, and ease of use.

Warranty and Service Agreements:

The BIB Filling Machine comes with a standard warranty covering manufacturing defects. Additionally, we provide extended service agreements tailored to your requirements, offering priority support and cost-effective maintenance solutions.

Our commitment is to support your business with reliable equipment and responsive service, ensuring your BIB Filling Machine operates at peak performance.

Packing and Shipping:

Our BIB Filling Machine is carefully packaged to ensure it arrives at your facility in perfect condition. The machine is securely placed in a sturdy wooden crate with ample cushioning materials to protect against any impact during transit. All movable parts are locked and secured to prevent damage. Additionally, the packaging is designed to withstand various weather conditions and handling stresses during shipping.

For shipping, we offer multiple options including sea freight, air freight, and road transport, depending on your location and urgency. The BIB Filling Machine is shipped with all necessary documentation, including user manuals, installation guides, and warranty certificates. We also provide assistance with customs clearance and offer tracking services to keep you informed throughout the delivery process.

Upon arrival, our technical support team is available to assist with installation, setup, and training to ensure your BIB Filling Machine operates efficiently from day one. We prioritize safe packaging and reliable shipping to deliver a seamless experience for our customers worldwide.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!